INTRODUCTION :-

In hydraulic systems the pump is the main driving unit which converts the mechanical energy in to hydraulic energy.Pump pushes the fluid in to the system by creating a positive flow in the load direction.Pump converts the mechanical horsepower in to the hydraulic horse power.

All pumps work on the same principle by generating an increasing volume on the intake side and a decreasing volume at the discharge side.But different pumps vary in the way they are constructed and the way they operate.

TERMS RELATED TO PUMP :-

Displacement :-

The flow capacity of the pump is normally expressed as the displacement per revolution.Displacement is the volume of fluid displaced per one revolution.Normally displacement is expressed in cc/rev or gallon per revolution.

Pump delivery or flow:-

Pump delivery or flow is defined as the volume of fluid displaced per minute.It is normally expressed in terms of liter per minute(LPM) or gallon per minute(GPM).

Volumetric efficiency :-

Theoretically pump delivers a volume that is equal to the displacement volume per revolution but practically the delivery of pump is less than the theoretical value due to internal leakage.Volumetric efficiency is defined as the ratio of actual flow delivered to the theoretical delivery.

Volumetric efficiency%=(actual out put/theoretical output) x 100

For example if a pump's theoretical output is 10 gpm but in practical testing it delivers 9 gpm then volumetric efficiency will be 90 percent.

PUMP RATINGS:-

Pump is generally rated by it's maximum operating pressure capability and the maximum output flow or delivery at a given drive speed.

PUMP POWER CALCULATION FORMULA :-

TYPES OF PUMP:-

there are basically two types of pump

1.Non positive displacement type.

In case of non positive displacement type pump the restriction to the flow is only friction in the pipe and the potential head(weight of fluid itself).

Normally these pumps work on the principle of centrifugal force hence called as centrifugal pumps.The fluid coming into the pump inlet is thrown out by rapidly moving impeller.There is no positive seal between the inlet and outlet ports.

It is possible to completely block the outlet port while the pump is running.As the resistance to flow increases the out put is reduced .Output depends on the impeller driven speed.

2.Positive displacement type.

Positive displacement type pump is most commonly used in industrial hydraulic systems.It delivers a specific amount of volume per every stroke or cycle or revolution.It is again classified into two types.

a.Fixed displacement type.

b.Variable displacement type.

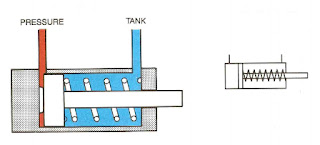

examples of positive displacement pump are gear pumps,vane pumps and piston pumps.

In hydraulic systems the pump is the main driving unit which converts the mechanical energy in to hydraulic energy.Pump pushes the fluid in to the system by creating a positive flow in the load direction.Pump converts the mechanical horsepower in to the hydraulic horse power.

All pumps work on the same principle by generating an increasing volume on the intake side and a decreasing volume at the discharge side.But different pumps vary in the way they are constructed and the way they operate.

TERMS RELATED TO PUMP :-

Displacement :-

The flow capacity of the pump is normally expressed as the displacement per revolution.Displacement is the volume of fluid displaced per one revolution.Normally displacement is expressed in cc/rev or gallon per revolution.

Pump delivery or flow:-

Pump delivery or flow is defined as the volume of fluid displaced per minute.It is normally expressed in terms of liter per minute(LPM) or gallon per minute(GPM).

*pump delivery is directly proportional to the pump drive shaft speed.

*pump delivery depends on the system operating pressure.At no load conditions it provides maximum flow but under certain operating pressure it provides minimum flow.If the pressure is very high the pump flow is bypassed to the tank as the pump is design is made for certain maximum pressure.Volumetric efficiency :-

Theoretically pump delivers a volume that is equal to the displacement volume per revolution but practically the delivery of pump is less than the theoretical value due to internal leakage.Volumetric efficiency is defined as the ratio of actual flow delivered to the theoretical delivery.

Volumetric efficiency%=(actual out put/theoretical output) x 100

For example if a pump's theoretical output is 10 gpm but in practical testing it delivers 9 gpm then volumetric efficiency will be 90 percent.

PUMP RATINGS:-

Pump is generally rated by it's maximum operating pressure capability and the maximum output flow or delivery at a given drive speed.

*Pump pressure capability is specified by the pump manufacturer depending on the maximum service life expectancy of the pump.

*If the operating service conditions are heavy or high pressure then the pump service life is reduced and may get severe damage.PUMP POWER CALCULATION FORMULA :-

HYDRAULIC HORSE POWER = GPM(flow) X PSI(pressure max)X 0.000583

HYDRAULIC KILOWATTS = LPM(flow) X BAR(pressure max) X 0.001667TYPES OF PUMP:-

there are basically two types of pump

1.Non positive displacement type.

In case of non positive displacement type pump the restriction to the flow is only friction in the pipe and the potential head(weight of fluid itself).

Normally these pumps work on the principle of centrifugal force hence called as centrifugal pumps.The fluid coming into the pump inlet is thrown out by rapidly moving impeller.There is no positive seal between the inlet and outlet ports.

It is possible to completely block the outlet port while the pump is running.As the resistance to flow increases the out put is reduced .Output depends on the impeller driven speed.

2.Positive displacement type.

Positive displacement type pump is most commonly used in industrial hydraulic systems.It delivers a specific amount of volume per every stroke or cycle or revolution.It is again classified into two types.

a.Fixed displacement type.

b.Variable displacement type.

examples of positive displacement pump are gear pumps,vane pumps and piston pumps.